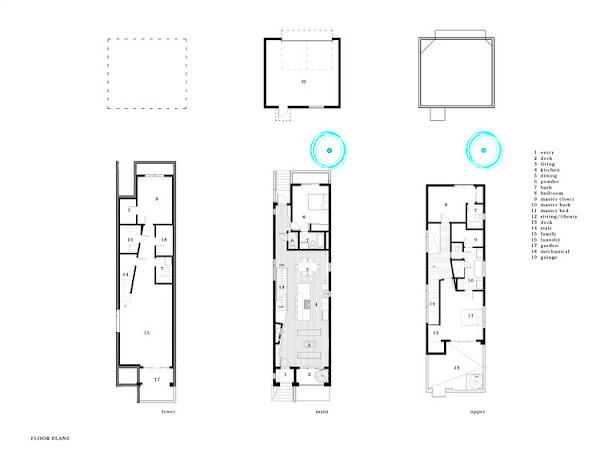

| Floor plans |

| Manufacturing in factory |

| On-site Assembly |

| About Tomecek Studio |

| Awards |

| LEED Certified, LEED-Home Pilot Program |

| 2008 Builder Magazine Grand Award |

| AIA Colorado Citation Award |

| AIA Colorado North Chapter Merit Award |

| AIA Colorado YAAG Built Architecture Award |

| Project | 32nd Modular |

| Architects | Tomecek Studio |

| Area | 2,750 square feet |

| Manufacturing time (80% completed in factory) | 3 weeks |

| Assembly time | 4,5 hours |

| Project completion time | 4,5 month |

| Location | Denver, Colorado |

| Year | 2007 |

When Brad Tomecek and his family outgrew their Denver loft and decided to swap it for a single-family home, the architect took the opportunity to experiment with an alternative building technique.

He purchased a narrow 25-foot-by-125-foot infill lot within walking distance to downtown, and, along with his colleagues at Studio H:T, designed a 2,750-square-foot modular house to be built in a factory. “It was an experiment to bring modern green design through the prefab process,” says Tomacek. “It saves time and reduces material waste to just 5 percent.”

The first LEED Silver–certified modular house in the state, it has a poured-in-place foundation with two boxes stacked above. “Because the site borders a commercial area, the zoning let us go a little higher than usual,” Tomacek explains. “That allowed for three stories including a basement.” Sliding the top box back a few feet created an upper southern deck and a covered rear entry area.

The project took just four-and-a-half months from start to finish. “We went from a foundation to a full frame structure in about five hours,” says Tomecek. “It was a good experience, and now we have another tool in our toolbox.”

Description by architect

This project tests the theory of bringing high quality design to a prefabricated factory setting. Enrolled in the LEED-Home Pilot, this residence completed certification. The modular home was conceived as two boxes that slide above one another to create outdoor living space and a lower covered rear entry. The passive solar design invites large amounts of light from the south while minimizing openings to the east and west. Factory construction saves both time and costs while reducing waste and using a controlled labor force.

Built in a factory north of Denver, the home arrived by flatbed truck in two pieces and was craned into place in about 4 hours providing a fast, sustainable, cost effective alternative to traditional homebuilding techniques. Upgraded lighting fixtures, plumbing fixtures, doors, door hardware, windows, tile and bamboo flooring were incorporated into the design. 80% of the residence was completed in the factory in less than 3 weeks and other items were finished on site including the exterior stucco, garage, metal railing and stair.

Stack-Slide-Stitch describes the conceptual process of how to tie together two distinct modular boxes. Stack refers to setting one modular directly on top of the other. Slide refers to the action that creates an upper southern deck area while simultaneously providing a covered rear entry area. The stitching or interlocking occurs with the upward extension of the lower volume with the front deck walls and with the rear two story vertical.

Floor plans

Manufacturing in factory

On-site assembly

About Tomecek Studio

The thoughtful, collaborative and lasting creation of architecture has the ability to impact the quality of life for those who use it. Tomecek Studio Architecture is dedicated to crafting unique and responsive spaces that go above and beyond the standard building experience.

We operate with a spirit of curiosity through craft and exploration. Our observations become the basis for our actions. We employ a collaborative process to provide creative solutions to our client’s specific circumstances. Ultimately, we craft places that live in memory based on the sculpting of light, surface, material and space.

Quality is the ultimate measure of value.

Design Excellence – We believe in the extraordinary power of design to influence the quality of life.

Integrity – We stake our reputation and found our relationships on honesty, trust, respect and financial integrity. We desire clients who believe in the same.

Innovation – We challenge the status quo in order to access improved processes and technologies. We explore prefab and modular methods both old and new to yield experientially innovative spaces.

Collaboration – We take time to listen. We iterate in a co-creative process with clients, consultants and contractors.

Environmental Stewardship – We lead by example, providing clients with projects that are sustainable and responsible. We believe in taking actions as designers to minimize the human impact on the world.

Outreach – We evangelize the power of prefab and modular design through teaching, mentorship, community involvement and public speaking.

Shipping Container Cabins and Homes by Tomecek Studio, Colorado

| Address | 3222 Tejon Street Studio C, Denver, CO 80211, USA |

| Phone | +1 303-955-0562 |

| Email 1 | mail@tomecekstudio.com |

| Email 2 | project@tomecekstudio.com |

| Houzz | https://www.houzz.com/professionals/architects-and-building-designers/tomecek-studio-architecture-pfvwus-pf~663411000 |

| https://www.instagram.com/tomecekstudio/ | |

| Website | tomecekstudio.com |

First LEED Silver Certified Prefab Modular Home in Colorado, Denver